Wastewater treatment

Wastewater treatment is a process used to remove contaminants from wastewater or sewage and convert it into an effluent that can be returned to the water cycle with acceptable impact on the environment, or reused for various purposes (called water reclamation).[1] The treatment process takes place in a wastewater treatment plant (WWTP), also referred to as a Water Resource Recovery Facility (WRRF) or a Sewage Treatment Plant (STP) in the case of domestic wastewater. Pollutants in wastewater are removed, converted or broken down during the treatment process.

.jpg.webp)

The treatment of wastewater is part of the overarching field of sanitation. Sanitation also includes the management of human waste and solid waste as well as stormwater (drainage) management.[2] The main by-product from wastewater treatment plants is sewage sludge which is usually treated in the same or another wastewater treatment plant.[3]:Ch.14 Biogas can be another by-product if anaerobic treatment processes are used.

Processes

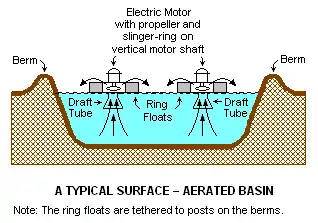

The processes involved in waste-water treatment include physical processes such as settlement or flotation and biological processes such as aerated lagoons, activated sludge, or bio-films in trickling filters. Other physical methods such as filtration through sieves may be used in specialised circumstances such as de-watering waste-water sludge.

To be effective, sewage must be conveyed to a treatment plant by appropriate pipes and infrastructure, and the process itself must be subject to regulation and controls. Some wastewaters require specialized treatment methods. At the simplest level, treatment of sewage and most wastewaters is carried out through separation of solids from liquids, usually by sedimentation. By progressively converting dissolved material into solids, usually a biological floc, which is then settled out, an effluent stream of increasing purity is produced.[3][4]

Phase separation

Phase separation transfers impurities into a non-aqueous phase. Phase separation may occur at intermediate points in a treatment sequence to remove solids generated during oxidation or polishing. Grease and oil may be recovered for fuel or saponification. Solids often require dewatering of sludge in a wastewater treatment plant. Disposal options for dried solids vary with the type and concentration of impurities removed from water.[5]

.jpg.webp)

Sedimentation

Solids such as stones, grit, and sand may be removed from wastewater by gravity when density differences are sufficient to overcome dispersion by turbulence. This is typically achieved using a grit channel designed to produce an optimum flow rate that allows grit to settle and other less-dense solids to be carried forward to the next treatment stage. Gravity separation of solids is the primary treatment of sewage, where the unit process is called "primary settling tanks" or "primary sedimentation tanks."[6] It is also widely used for the treatment of other types of wastewater. Solids that are denser than water will accumulate at the bottom of quiescent settling basins. More complex clarifiers also have skimmers to simultaneously remove floating grease such as soap scum and solids such as feathers, wood chips, or condoms. Containers like the API oil-water separator are specifically designed to separate non-polar liquids.[7]

Oxidation

Oxidation reduces the biochemical oxygen demand of wastewater, and may reduce the toxicity of some impurities. Secondary treatment converts organic compounds into carbon dioxide, water, and biosolids. Chemical oxidation is widely used for disinfection.

.jpg.webp)

Biochemical oxidation

Secondary treatment by biochemical oxidation of dissolved and colloidal organic compounds is widely used in sewage treatment and is applicable to some agricultural and industrial wastewaters. Biological oxidation will preferentially remove organic compounds useful as a food supply for the treatment ecosystem. Concentration of some less digestible compounds may be reduced by co-metabolism. Removal efficiency is limited by the minimum food concentration required to sustain the treatment ecosystem.[8]

Chemical oxidation

Chemical (including electrochemical) oxidation is used to remove some persistent organic pollutants and concentrations remaining after biochemical oxidation.[9] Disinfection by chemical oxidation kills bacteria and microbial pathogens by adding ozone, chlorine or hypochlorite to wastewater.[3]:1220

Polishing

Polishing refers to treatments made following the above methods. These treatments may also be used independently for some industrial wastewater. Chemical reduction or pH adjustment minimizes chemical reactivity of wastewater following chemical oxidation.[10] Carbon filtering removes remaining contaminants and impurities by chemical absorption onto activated carbon.[3]:1138 Filtration through sand (calcium carbonate) or fabric filters is the most common method used in municipal wastewater treatment.

Types of treatment plants

Wastewater treatment plants may be distinguished by the type of wastewater to be treated, i.e. whether it is sewage, industrial wastewater, agricultural wastewater or leachate.

Sewage treatment plants

A typical municipal sewage treatment plant in an industrialized country may include primary treatment to remove solid material, secondary treatment to digest dissolved and suspended organic material as well as the nutrients nitrogen and phosphorus, and – sometimes but not always – disinfection to kill pathogenic bacteria. The sewage sludge that is produced in sewage treatment plants undergoes sludge treatment. Larger municipalities often include factories discharging industrial wastewater into the municipal sewer system. The term "sewage treatment plant" is sometimes replaced with the term "wastewater treatment plant".[3] Sewage can also be treated by processes using "Nature-based solutions".

Tertiary treatment

Tertiary treatment is a term applied to polishing methods used following a traditional sewage treatment sequence. Tertiary treatment is being increasingly applied in industrialized countries and most common technologies are micro filtration or synthetic membranes. After membrane filtration, the treated wastewater is nearly indistinguishable from waters of natural origin of drinking quality (without its minerals). Nitrates can be removed from wastewater by natural processes in wetlands but also via microbial denitrification.[11] Ozone wastewater treatment is also growing in popularity, and requires the use of an ozone generator, which decontaminates the water as ozone bubbles percolate through the tank. The latest, and very promising treatment technology is the use aerobic granulation.[12]

Industrial wastewater treatment plants

Disposal of wastewaters from an industrial plant is a difficult and costly problem. Most petroleum refineries, chemical and petrochemical plants[3]:1412[13] have onsite facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the local and/or national regulations regarding disposal of wastewaters into community treatment plants or into rivers, lakes or oceans. Constructed wetlands are being used in an increasing number of cases as they provided high quality and productive on-site treatment. Other industrial processes that produce a lot of waste-waters such as paper and pulp production has created environmental concern, leading to development of processes to recycle water use within plants before they have to be cleaned and disposed.[14]

Industrial wastewater treatment plants are required where municipal sewage treatment plants are unavailable or cannot adequately treat specific industrial wastewaters. Industrial wastewater plants may reduce raw water costs by converting selected wastewaters to reclaimed water used for different purposes. Industrial wastewater treatment plants may reduce wastewater treatment charges collected by municipal sewage treatment plants by pre-treating wastewaters to reduce concentrations of pollutants measured to determine user fees.[15]

Although economies of scale may favor use of a large municipal sewage treatment plant for disposal of small volumes of industrial wastewater, industrial wastewater treatment and disposal may be less expensive than correctly apportioned costs for larger volumes of industrial wastewater not requiring the conventional sewage treatment sequence of a small municipal sewage treatment plant.[16]

An industrial wastewater treatment plant may include one or more of the following rather than the conventional primary, secondary, and disinfection sequence of sewage treatment:

- An API oil-water separator, for removing separate phase oil from wastewater.[17]

- A clarifier, for removing solids from wastewater.[18]

- A roughing filter, to reduce the biochemical oxygen demand of wastewater.[19]

- A carbon filtration plant, to remove toxic dissolved organic compounds from wastewater.[20]

- An advanced electrodialysis reversal (EDR) system with ion exchange membranes.

Agricultural wastewater treatment plants

Agricultural wastewater treatment for continuous confined animal operations like milk and egg production may be performed in plants using mechanized treatment units similar to those described under industrial wastewater; but where land is available for ponds, settling basins and facultative lagoons may have lower operational costs for seasonal use conditions from breeding or harvest cycles.[21]

Many farms generate nonpoint source pollution from surface runoff which is not controlled through a treatment plant. Farmers can install erosion controls and implement nutrient management plans to control runoff pollution.[22][23]:pp. 4–95–4–96

Leachate treatment plants

Leachate treatment plants are used to treat leachate from landfills. Treatment options include: biological treatment, mechanical treatment by ultrafiltration, treatment with active carbon filters, electrochemical treatment including electrocoagulation by various proprietary technologies and reverse osmosis membrane filtration using disc tube module technology.[24]

Disposal or reuse

Although disposal or reuse occurs after treatment, it must be considered first. Since disposal or reuse are the objectives of wastewater treatment, disposal ,or reuse options are the basis for treatment decisions. Acceptable impurity concentrations may vary with the type of use or location of disposal. Transportation costs often make acceptable impurity concentrations dependent upon the location of disposal, but expensive treatment requirements may encourage the selection of a disposal location on the basis of impurity concentrations. Ocean disposal is subject to international treaty requirements. International treaties may also regulate disposal into rivers crossing international borders. Water bodies entirely within the jurisdiction of a single nation may be subject to regulations of multiple local governments. Acceptable impurity concentrations may vary widely among different jurisdictions for disposal of wastewater to evaporation ponds, infiltration basins, or injection wells.[25]

Reuse of wastewater is essential to reduce water stress in cities, promote consciousness, and reduce pollutants into water bodies. Reused water can be used for multiple purposes such as “reclaimed and reused for crop and landscape irrigation, groundwater recharge, or recreational purposes.” There are two ways of wastewater reuse: direct and indirect reuse. Direct reuse entails using treated wastewater as it is, and indirect reused is diluting treated wastewater with another water source before further use.[26]

Global situation

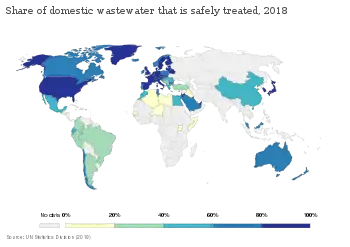

At the global level, an estimated 52% of wastewater is treated.[27] However, wastewater treatment rates are highly unequal around the world. For example, while high-income countries treat approximately 74% of their wastewater, low-income countries treat an average of just 4.2%. Improving wastewater treatment across the globe is crucial for reducing our pollution to the environment and achieve water quality improvements. For this reason, Sustainable Development Goal 6 has a Target 6.3 which is formulated as follows: "By 2030, improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials, halving the proportion of untreated wastewater and substantially increasing recycling and safe reuse globally."[28] The corresponding Indicator 6.3.1 is the "proportion of wastewater safely treated" (see map on the right for 2018). For example, Algeria, Senegal, Niger, Libya, Uganda, Somalia, and Iraq do not treat domestic wastewater safely yet.

By country

European Union

India

Libya

In Libya, wastewater treatment is managed by the general company for water and wastewater in Libya, which falls within the competence of the Housing and Utilities Government Ministry. There are approximately 200 wastewater treatment plants across the nation, but few plants are functioning. In fact, the 36 larger plants are in the major cities; however, only nine of them are operational, and the rest of them are under repair.[33]

The largest operating wastewater treatment plants are situated in Sirte, Tripoli, and Misurata, with a design capacity of 21,000, 110,000, and 24,000 m3/day, respectively. Moreover, a majority of the remaining wastewater facilities are small and medium-sized plants with a design capacity of approximately 370 to 6700 m3/day. Therefore, 145,800 m3/day or 11 percent of the wastewater is actually treated, and the remaining others are released into the ocean and artificial lagoons although they are untreated. In fact, nonoperational wastewater treatment plants in Tripoli lead to a spill of over 1,275, 000 cubic meters of unprocessed water into the ocean every day.[33]United States

See also

References

- "wastewater treatment | Process, History, Importance, Systems, & Technologies". Encyclopedia Britannica. October 29, 2020. Retrieved 2020-11-04.

- "Sanitation". Health topics. World Health Organization. Retrieved 2020-02-23.

- Metcalf & Eddy, Inc. (2003). Wastewater Engineering: Treatment and Reuse (4th ed.). New York: McGraw-Hill. ISBN 0-07-112250-8.

- Primer for Municipal Waste water Treatment Systems (Report). Washington, DC: US Environmental Protection Agency (EPA). 2004. EPA 832-R-04-001..

- Ajay Kumar Mishra Smart Materials for Waste Water Applications ,Wiley-Scrivener 2016 ISBN 111904118X https://onlinelibrary.wiley.com/doi/book/10.1002/9781119041214

- Gupta, Ashok; Yan, Denis, eds. (2016-01-01), "Chapter 16 - Gravity Separation", Mineral Processing Design and Operations (Second Edition), Amsterdam: Elsevier, pp. 563–628, ISBN 978-0-444-63589-1, retrieved 2020-11-30

- Weber, pp.111-138

- Steel & McGhee, pp. 477–521

- Weber, pp.363-408

- Weber, p.439

- Hopcroft, Francis (2014). Wastewater Treatment Concepts and Practices. Momentum Press.

- Wastewater Treatment : Advanced Processes and Technologies. 2012.

- Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants (1st ed.). John Wiley & Sons. LCCN 67019834.

- Byrd, J.F.; Ehrke, M.D.; Whitfield, J.I. (April 1984). "New Bleached Kraft Pulp Plant in Georgia: State of the Art Environmental Control". Journal (Water Pollution Control Federation). 56 (4): 378–385. JSTOR 25042250..

- Hammer, pp.300-302

- Kemmer, pp.40-4-40-11

- Patterson, p.180

- Kemmer, p.41-15

- Kemmer, p.23-11

- Patterson, p.210

- Reed, Middlebrooks & Crites, pp.6-8

- "Erosion". Washington, DC: US Natural Resources Conservation Service. Retrieved 2020-11-19.

- National Management Measures to Control Nonpoint Source Pollution from Agriculture (Report). EPA. July 2003. EPA 841-B-03-004.

- "Landfills Effluent Guidelines". EPA. 2018-03-16.

- Chambers, Phoenix (2019). Standard Methods for the Examination of Water and Wastewater. Scientific e-Resources. pp. 6–7. ISBN 9781839471667.

- "wastewater treatment | Process, History, Importance, Systems, & Technologies". Encyclopedia Britannica. Retrieved 2020-11-30.

- Jones, Edward R.; van Vliet, Michelle T. H.; Qadir, Manzoor; Bierkens, Marc F. P. (2021-02-08). "Country-level and gridded estimates of wastewater production, collection, treatment and reuse". Earth System Science Data. 13 (2): 237–254. doi:10.5194/essd-13-237-2021. ISSN 1866-3508.

- Ritchie, Roser, Mispy, Ortiz-Ospina (2018) "Measuring progress towards the Sustainable Development Goals." (SDG 6) SDG-Tracker.org, website

- "Council Directive 91/271/EEC of 21 May 1991 concerning urban waste-water treatment (91/271/EEC)". Retrieved 19 July 2009.

- "Urban Waste Water Directive Overview". European Commission. Retrieved 19 July 2009.

- Schellenberg, Tatjana; Subramanian, Vrishali; Ganeshan, Ganapathy; Tompkins, David; Pradeep, Rohini (2020). "Wastewater Discharge Standards in the Evolving Context of Urban Sustainability–The Case of India". Frontiers in Environmental Science. 8. doi:10.3389/fenvs.2020.00030. ISSN 2296-665X. S2CID 215790363.

- Kaur, R; Wani, SP; Singh, AK. "Wastewater production, treatment and use in India" (PDF). AIS. Retrieved 2020-11-17.

- "Wastewater Treatment Plants in Libya: Challenges and Future Prospects". International Journal of Environmental Planning and Management.

- United States. Federal Water Pollution Control Act Amendments of 1972. Pub.L. 92–500 Approved October 18, 1972. Amended by the Clean Water Act of 1977, Pub.L. 95–217, December 27, 1977; and the Water Quality Act of 1987, Pub.L. 100–4, February 4, 1987.

- "National Pollutant Discharge Elimination System". EPA. 2020-02-21.

- EPA. "Secondary Treatment Regulation." Code of Federal Regulations, 40 CFR Part 133.

- "Industrial Effluent Guidelines". EPA. 2020-02-12.

Sources

- Hammer, Mark J. (1975). Water and Waste-Water Technology. New York: John Wiley & Sons. ISBN 0-471-34726-4.

- Kemmer, Frank N. (1979). The Nalco Water Handbook. New York: McGraw-Hill Book Company.

- Patterson, James W. (1980). Wastewater Treatment Technology. Ann Arbor, Michigan: Ann Arbor Science. ISBN 0-250-40086-3.

- Ramseur, Jonathan L. (September 22, 2017). Wastewater Infrastructure: Overview, Funding, and Legislative Developments (PDF). Washington, DC: Congressional Research Service. Retrieved 17 December 2017.

- Reed, Sherwood C.; Middlebrooks, E. Joe; Crites, Ronald W. (1988). Natural Systems for Waste Management and Treatment. New York: McGraw-Hill Book Company. ISBN 0-07-051521-2.

- Weber, Walter J. Jr. (1972). Physicochemical Processes for Water Quality Control. New York: Wiley-Interscience. ISBN 0-471-92435-0.

External links

| Wikimedia Commons has media related to Wastewater treatment. |

- Transnational Ecological Project – Industrial wastewater treatment (Russia)

- Water Environment Federation – Professional association focusing on wastewater treatment